Steel Fixing and Formwork

Precision and Strength for Lasting Pool Foundations

At Peninsula Pool Steel Fixing, our Steel Fixing & Formwork services form the backbone of any structurally sound pool project. Our team brings years of expertise to ensure each pool foundation is both durable and precise, providing stability that endures. From meticulous planning to the final placement of steel, we cover every detail, laying the groundwork for a long-lasting and secure pool.

Our approach is tailored to each project’s specific requirements, whether for residential homeowners, owner-builders, commercial pool builders, or contractors. By focusing on safety, durability, and compliance with industry standards, we deliver a foundation that holds strong, ensuring your pool remains secure and functional for years to come.

What is Steel Fixing & Formwork?

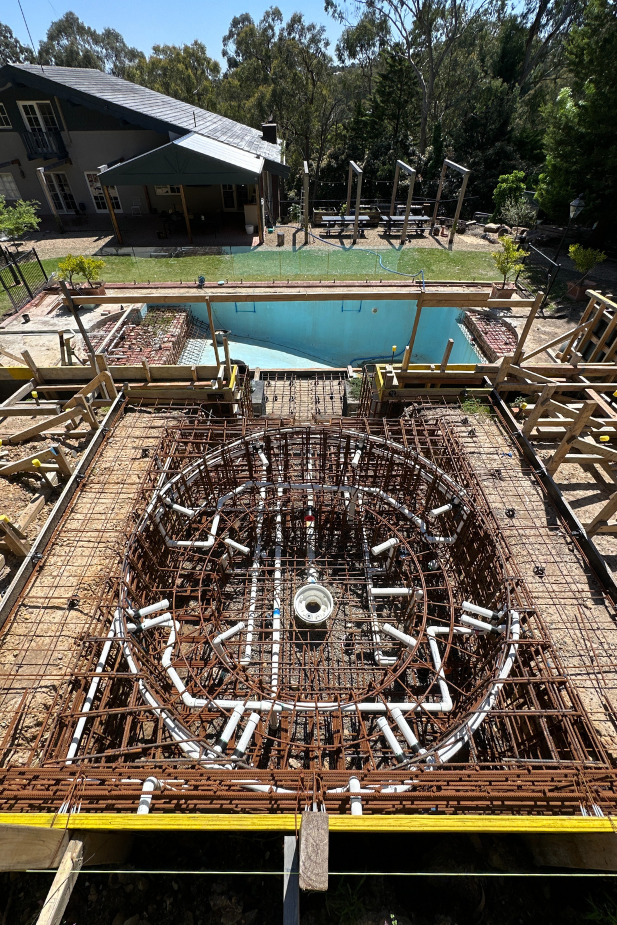

Steel fixing and formwork are essential processes in pool construction that create a strong, stable foundation to support the pool structure. Steel fixing involves securing steel bars and mesh within the framework of the pool to reinforce its structure, adding critical strength and durability. Formwork, on the other hand, is the temporary or permanent mold into which concrete is poured, defining the pool's shape and providing support during construction. Together, these processes ensure that the pool can withstand the pressure of water and external forces, making them fundamental steps in achieving a long-lasting and resilient pool.

Our Steel Fixing Process

-

Consultation and Site Assessment

Every successful project begins with a consultation and on-site evaluation. We assess factors like soil type, pool shape, and local conditions that may affect the steel structure. This stage allows us to design an approach that matches both the site requirements and the client's vision.

01.

-

Structural Design and Planning

Working closely with engineers, our team ensures the design aligns with structural requirements. We plan steel reinforcement according to project specifications, detailing the size, placement, and type of steel required to achieve optimal strength and durability for the pool.

02.

-

Precision Steel Placement

Our team carefully places steel bars and mesh to provide robust reinforcement throughout the pool. We use high-quality steel to match durability standards, and our placement ensures even weight distribution, which helps prevent cracking and structural issues down the line.

03.

-

Securing Steel for Maximum Stability

Each piece of steel is fastened securely with ties and positioned to maintain stability under the weight of concrete. Our secure tying technique is tailored to resist shifting during the formwork and pouring processes, ensuring the structure's integrity.

04.

-

Safety, Compliance Checks

Before proceeding to formwork, we conduct rigorous safety inspections and compliance checks to ensure all steel fixing is up to code. This stage guarantees that the structure adheres to local building regulations, minimising potential issues during construction.

05.

Our Formwork Process

Formwork is the mold into which concrete is poured to shape the pool structure. Our formwork process involves careful planning and skilled execution to achieve a precise pool layout.

Custom Formwork Design 01

-

Each pool requires custom formwork designed to fit the specific dimensions and shape of the pool. We use a mix of durable materials to create a sturdy mold that holds its shape under the weight and pressure of wet concrete.

Precise Framework Setup 02.

-

Once designed, our team sets up the framework on-site, ensuring it follows the pool’s contours precisely. This is crucial to achieving the desired pool shape and is part of our commitment to precision in every detail of the construction.

Reinforcement Support Systems 03

-

To enhance stability, we integrate additional support systems, preventing the formwork from shifting during the concrete pour. This setup guarantees that the final structure aligns perfectly with the intended design.

Inspection and Final Adjustments 04

-

Before concrete pouring, our team inspects the formwork for accuracy and stability. We make any necessary adjustments to guarantee that the formwork remains secure during the concrete pour, ensuring a flawless foundation.

Why Choose Peninsula Pool Steel Fixing for Steel Fixing & Formwork?

Expertise in Complex Projects 01

-

Our team is experienced in handling projects of all complexities, from simple backyard pools to intricate commercial designs.

Commitment to Quality, Safety 02.

-

We follow industry best practices and strictly adhere to safety protocols, ensuring that every project meets the highest quality standards.

Efficient and Reliable Process 03

-

With streamlined processes and an organised team, we ensure efficient project timelines without compromising on detail.

Frequently Asked Questions

What is the purpose of steel fixing in pool construction?

Steel fixing involves placing steel bars and mesh within the pool structure to provide reinforcement and support. It strengthens the pool, helping it resist water pressure and preventing cracking or shifting over time.

Why is formwork essential in pool building?

Formwork serves as the mold that shapes the pool. It holds concrete in place until it sets, creating the pool’s structure. High-quality formwork ensures precision in shape, stability, and long-term durability for the pool.

How long does the steel fixing and formwork process take?

The timeline varies based on the pool size and complexity, but generally, steel fixing and formwork take about 1–2 weeks. We provide an accurate timeline after assessing your project’s specific needs.

Is steel fixing necessary for every pool?

Yes, steel fixing is crucial for structural integrity. Without steel reinforcement, pools are prone to cracks, shifts, and damage over time, especially under the pressure of water and external forces.

What materials are used for formwork?

We use high-quality, durable materials for formwork, such as plywood and steel, which can withstand the pressure of the concrete. This ensures the mold holds its shape and provides a smooth, even finish.

Can steel fixing and formwork be customised to my pool’s design?

Absolutely. Our steel fixing and formwork services are fully customisable to fit any pool shape or size. We work closely with you to ensure the design aligns with your vision and structural requirements.

Do you handle permits and inspections?

Yes, we assist with permits and arrange for inspections as needed, ensuring compliance with local regulations for safe and secure pool construction.

What factors influence the cost of steel fixing and formwork?

The main factors are the pool’s size, complexity, site conditions, and any custom requirements. We provide a detailed quote after our initial consultation.

How does steel fixing help with pool maintenance?

A well-reinforced pool is less likely to develop cracks or structural issues, which can lead to costly repairs. Steel fixing helps ensure the longevity of your pool, reducing the need for ongoing structural maintenance.

How can I get started with my pool construction project?

Simply contact us for a consultation! We’ll discuss your vision, assess your site, and create a detailed plan to make your pool project a reality.

Need a custom quote? Just leave a request below

Get Custom Quote